-

category:Solid liquid separation equipment

- The number of clicks:

- Release date:2020/03/12

- message

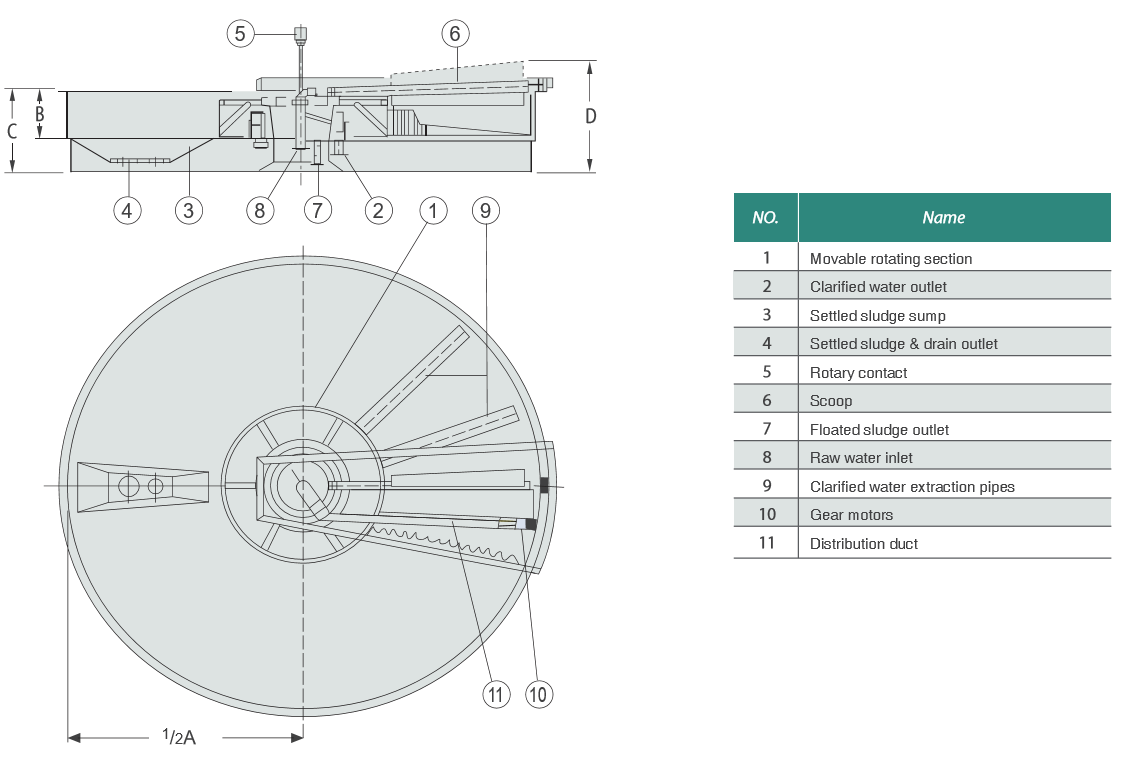

DAF-R dissolved air flotation clarifier

Applications

1. Paper making white water treatment and fibre recovery.

2. Physical treatment of industrial wastewater such as dyeing wastewater,chemical wastewater, light Industry wastewater, food wastewater and pharmaceutical waste.

3. Separation of water and biologic floccules in biotreatment (instead second setting tank).

4. Reuse of cooling water in production and water baths, other waste water treatment for separating the solid and liquid.

Features

1. The retention time is short, only 3 minutes are required.

2. Super high surface load: 180~200 m³/(m²·d).

3. The water depth of air flotation basin is approximately 40cm, which will not change due to different handling capacity.

4. The above-mentioned three features make the volume, area and height of our company's air flotation basin small and compact. Removal ratio for suspended solid is above 90-95%, after-treated concentration of suspended solid maintains 30-50mg/l.

5. The unit weight of air flotation basin is light. It can be mounted on everywhere. When it is in-service use, the elevated installation can utilize its space as well as its after-treated clear water and scum more efficiently, the costs for design of sludge pump and motive power can be saved because of gravity action.

6. The costs for stainless steel's manufacturing, operation and maintenance are low, and water-producing effect is ideal under the condition no medicament is added.

7. The equipment can be used in sludge concentration basin, making scum to concentrate to 5-8%, increasing dehydration effect for sludge and relieving treatment burden for sludge.

8. All central collectors with special phosphorus-copper material and exterior cable steel rope racks are equipped up to the standard.

9. Motor shaft has a particular plug-in structure.

Construction

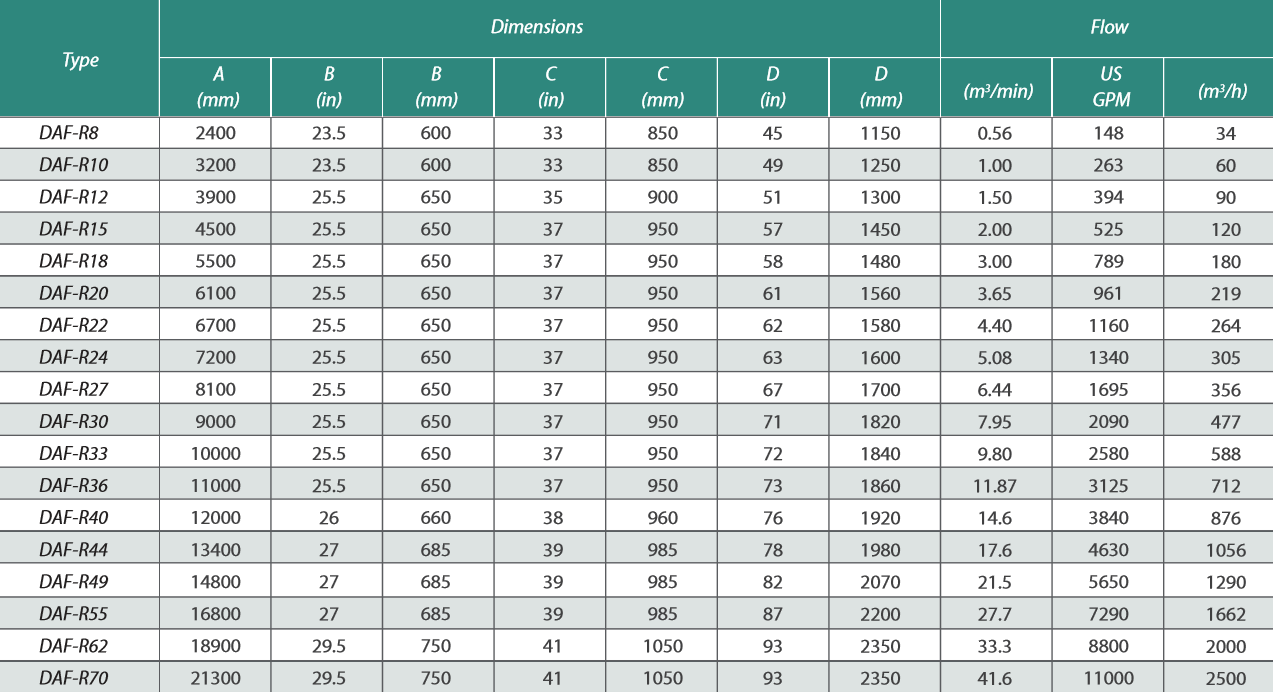

Performance parameters

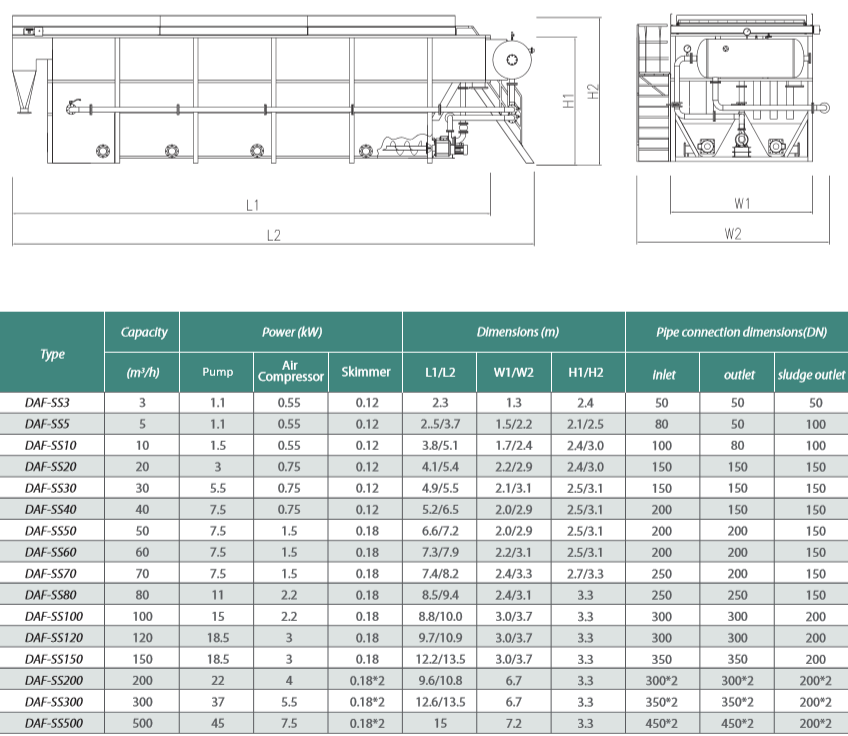

DAF-S dissolved air flotation clarifier

Applications

1. For treating suspended solids or contaminants of gravity generally closed to or less than water, especially efficient for suspensions se ling slowly, remaining in suspension, or having a tendency to flo at.

2. Oil and Fats.

3. Food Industry effluents with high solids concentra on.

4. Sludge Thickening.

5. Galvanizing Electro plan ng.

6. Pharmaceu cal Industry.

7. Leather Industry, etc.

Features

1. High hydraulic load and less footprint.

2. High-rated clarifica on for high SS water (light par cles, oil and colloid).

3. Be er outlet water quality.

4. Effec vely minimize chemical consump on. 5. No blind angle in scum collec on chamber.

Carbon Steel surface finish and corrosion treatment

1. Sand Blas ng/ Shot Peening, ISO Sa≥2.5, epoxy Zinc Rich Primer, 50μm/coat.

2. Internal:

a) Epoxy Zinc-rich Primer, 50μm/coat×1;

b) Epoxy Mas c Paint, 100μm/coat×2~3;

c) Total film thickness: 250μm.

3. External:

a) Epoxy Zinc-rich Primer, 50μm/coat×1;

b) Epoxy Micaceous Iron Intermediate Paint, 50μm/coat×1;

c) Polyurethane Finish, 50μm/coat×1;

d) Total fil m thickness: ≥150μm.

Spraying Method: High-Pressure Airless Spraying Device Color: Light Sea Blue (PANTONE No.RAL5015), or according to customers’ demands.

Standards for Interface Flange

China: JB/T81-1994, PN 1.0

America: ANSI 150

Japan: JIS 10K

Bolts and Nuts

Liquid Part: SUS304 Uncontact Liquid Part: Carbon Steel Galvanized

Performance parameters

Product Catalog

中文

中文